MILL QUALITY ASSURANCE

Elevate your MQA Program with Dairyland Laboratories, guaranteeing feed quality and safety for livestock while complying with FDA regulations.

Elevate your MQA Program with Dairyland Laboratories, guaranteeing feed quality and safety for livestock while complying with FDA regulations.

Data and Reporting

Lab Certifications and Quality Assurance

Customer Experience

Complete packages and stand alone services, developed with mill quality assurance programs in mind

For commodities and grains:

NIR is available for whole plant corn, corn grain, ear corn, cereal grains, distiller’s grains, wheat midds, corn gluten feed, brewer’s grains, canola meal, soybean meal, soy hulls, blood meal, meat & bone meal, and beet pulp. Not all parameters are available for all feed types. For more information see our packages.

NIR Basic is good for monitoring feed quality providing all inputs for NRC01 energy calculations.

NIR Select enables you to evaluate across feeds with all inputs and outputs of the University of Wisconsin's Milk energy systems including NDFD and milk per ton.

NIR CNCPS 6.5+/Complete NASEM can elevate your quality assurance and provide your nutrition team with their own feed library with all recommended inputs for CNCPS and NASEM formulation including:

For complete feeds, abnormal samples, and precision minerals:

Tag Basic is a chemistry package for any feed types that includes crude protein, crude fiber, and ether extract. M9 is a popular mineral package add-on with Ca, P, Na.

H chemistry package provides crude protein and ether extract.

Mineral Packages are available to add on to any packages or stand alone for mineral mixes.

With the implementation of the Food Safety and Modernization Act (FSMA) in 2018, tracing mycotoxins throughout the food chain came into focus. Dairyland is committed to providing fast, accurate, and repeatable results, motivating us to invest in bringing our mycotoxin testing in-house. We are proud to offer the industry gold standard with HPLC-MS/MS using radiostable isotopes. To learn more about our methodology, why this matters, and our full offerings, check out our mycotoxins page.

At Dairyland, we are committed to ensuring the highest standards of quality and consistency in animal feed production. To assist our valued customers in this endeavor, we offer Mixer Tests, a comprehensive service designed to assess the variability in mixer performance and ensure thorough mixing of the grain or mineral mix.

Our Mixer Tests involve the sampling of 5-10 samples during the load-out process, selected to track the variability of a specific mineral or nutrient throughout the mixing process. We provide detailed reports that include statistical metrics such as standard deviation, offering valuable insights into the uniformity and thoroughness of mixing achieved by your equipment.

By leveraging our Mixer Tests, customers gain critical information that empowers them to optimize their mixer settings, enhance production efficiency, and ultimately deliver superior quality feed to their livestock.

| Coefficient of variation (CV) | Interpretation |

| 0-5% | Superior - meets or exceeds all industry standards |

| 5-10% | Excellent - meets or exceeds most feed manufacturing standards |

| 10-15% | Good - acceptable for high forage ruminant diets |

| 15-25% | Fair - may be acceptable but room for improvement |

| 25%+ | Poor - may negatively impact animal performance |

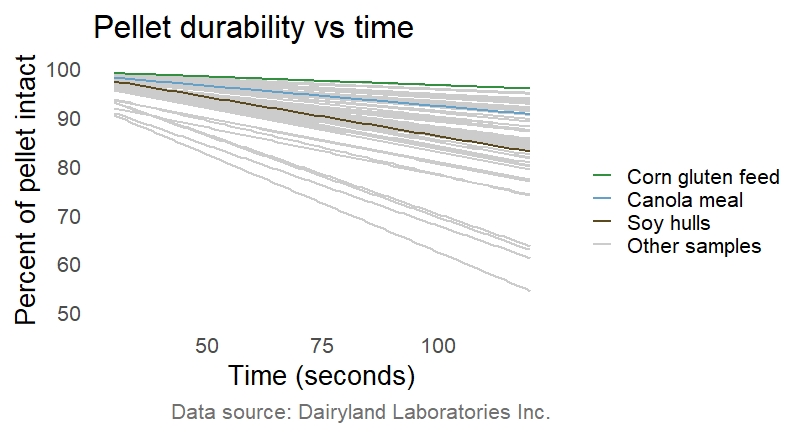

The durability of feed pellets is crucial to their physical integrity as they move through feed handling systems, while also impacting their palatability to livestock. While traditional “tumble can” metrics for pellet quality have been available since the 1960’s, some implementations struggle to truly differentiate durability across a range of pellet types. After an in-house assessment of several testing options, we’ve landed on the Holmen NHP100 as our pellet durability analysis of choice and are now offering a Pellet Durability testing package.

The Holmen NHP100 is designed to simulate the types of abuse pellets undergo as they move through feed transportation systems, using high-pressure air to bounce pellets off hard surfaces, some smooth and some grated, at multiple angles. Then at fixed time intervals of 30, 60, 90, and 120 seconds, we quantify the amount of fines which are automatically filtered through a 2.5 mm screen. For a clearer picture of how the analysis works, check out this video.

In our testing, we’ve found individual ingredient pellets to range in durability from 80-98% at 120 seconds, with mixed feed pellets having as little as 30% of pellets intact after 30 seconds. Using the slope of measurements at multiple time points, pellet durability reports also include an estimated time to 50%, indicating how long it takes 50% of pellets to degrade into fines.

A Grain Particle Size report will include the weight and percentage of the same retained on each sieve as well as calculations of the Mean Particle Size (MPS) and 1 Standard Deviation Distribution. Typical MPS values found for various processing methods are as follows:

| Feed Grain | MPS |

| Fine Ground - Dry Corn | <750 |

| Medium Grind - Dry Corn | 750 - 1000 |

| Coarse Ground - Dry Corn | >1000 |

| Whole - Dry Corn | >4000 |

| Fine Ground - High Moisture Corn | <1000 |

| Coarse Grind - High Moisture Corn | 1000 - 2500 |

| Rolled - High Moisture Corn | 1000 - 2500 |

| Coarse Rolled - High Moisture Corn | >2500 |

| Whole - High Moisture Corn | >4000 |

| Snaplage | 750 - 2000 |

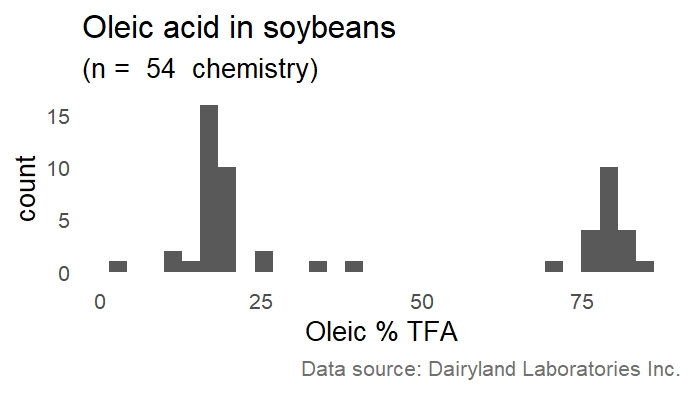

High-oleic soybeans (aka Plenish beans), provide unique feeding value to dairy cattle and can be easily identified by their fatty acid profile.

Soybeans, roasted soybeans, and soybean meal can all be submitted for fatty acid analysis.

Dairyland is in the final stages of NIR calibration development for both in-field and lab equipment.

Feed additives like monensin, lasalocid, and medications often offer on-site test kits that utilize tracers to identify the presence and concentration of these ingredients.

When lab-based chemistry is warranted, or third-party verification is needed, contact us for specific sampling instructions unique to these additives.

© 2024 Dairyland Laboratories, Inc.